Explorer Line

Efficient and reliable cooling for project-specific requirements

The STULZ Explorer Line is a series of air-cooled chiller systems that is suitable for numerous different uses. The units of this product series combine high-quality components with the ability to fulfill project-specific requirements. We offer a portfolio of state-of-the-art industrial water chillers that are kind to your budget and flexible enough to be adapted to all customer requirements.

Product Overview

Most important benefits

- Microchannel condensers for improved heat transfer, less refrigerant and lower air-side pressure drops for maximum performance

- Two independent refrigerant circuits ensure high redundancy.

- Thanks to its compact size and light weight, the unit is suitable for almost every installation.

Most important features

- Easy and thus cost-effective transport via ISO container all over the world

- Outdoor installation on the roof or next to the building

- Suitable for outdoor temperatures from -40°C to +45°C

- Cold water outlet temperatures from -7°C to +25°C possible

Most important technical data

- 138 models in 10 sizes

- Cooling capacity (kW): 80 – 1,200

- Microchannel condensers for improved heat transfer, less refrigerant and lower air-side pressure drops for maximum performance

- Two independent refrigerant circuits ensure high redundancy.

- Thanks to its compact size and light weight, the unit is suitable for almost every installation.

- Generous switch gear cabinet with space for numerous optional electrical accessories and the customer’s individual requirements for chilled water generation

- Low TCO thanks to Free Cooling

- Electronic expansion valve as standard controlled by the SEC.blue electronic controller

- Easy and thus cost-effective transport via ISO container all over the world

- Outdoor installation on the roof or next to the building

- Suitable for outdoor temperatures from -40°C to +45°C

- Cold water outlet temperatures from -7°C to +25°C possible

- Available in 138 combined models:

- Free Cooling

- Low noise

- Scroll and screw compressor

| WPAmini | WPA | WSA | |

| Cooling capacity | 80 – 160 | 160 – 565 | 370 – 1,200 |

| Refrigerant | R410a | R410a | R134a (GWP: 1,430) |

| (GWP: 2,088) | (GWP: 2,088) | R513a (GWP: 573) | |

| Compressor | Scroll | Scroll | Screw |

| Cooling circuits | 2 | 2 | 2 |

| Level (%) | 25 – 100 | 17/25 – 100 | 12,5 – 100 |

| Dimensions | Length (mm): 3,650 Depth (mm): 1,370 Height (mm): 2,316 | Length (mm): 3,140 – 7,130 Depth (mm): 2,208 – 2,208 Height (mm): 2,406 – 2.406 | Length (mm): 4,255 – 11,980 Depth (mm): 2,278 – 2,278 Height (mm): 2,473 – 2,473 |

Need more information?

Download our brochure!

STULZ Chiller Range - Video

All details about Explorer (Line)

Climate. Customized.

From standard units to fully customized solutions

The ability to offer such a wide range to customers is the embodiment of our philosophy, "Climate. Customized.". Size, design, cooling capacity or control: STULZ's Explorer Line can be precisely adapted to your individual requirements. In addition, a variety of options and equipment are available to achieve the optimum result.

Model overview for your mission-critical applications

Data center and telecommunications

Ambient air temperature: from -20°C to +45°C

Chilled water: inlet +12°C to >+22°C

Chilled water: outlet +7°C to >+18°C

Process and industrial cooling

Ambient air temperature: from -20°C to +45°C

Chilled water: inlet +0°C to >+30°C

Chilled water: outlet -5°C to >+25°C

Comfort air conditioning

Ambient air temperature: from -20°C to +45°C

Chilled water: inlet +12°C to >+20°C

Chilled water: outlet +6°C to >+15°C

STULZ Explorer air-cooled range

WPAmini: 80 – 160 kW

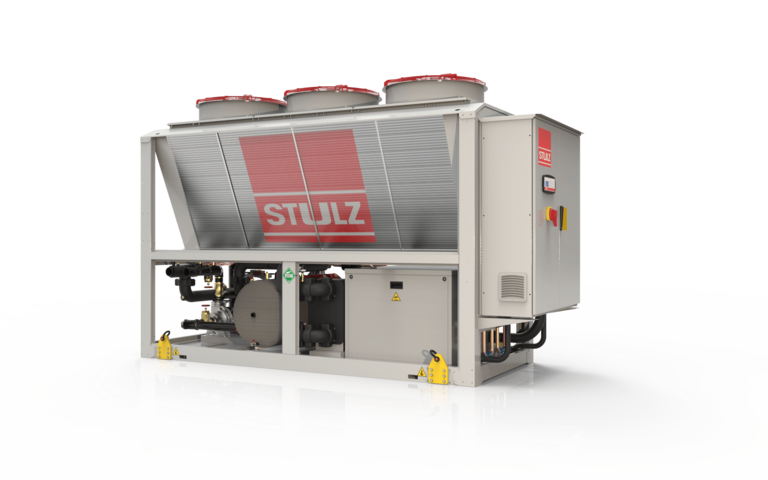

STULZ Explorer WPAmini

Air-cooled chiller systems for a cooling capacity of 80 to 160 kW

WPA: 160 – 565 kW

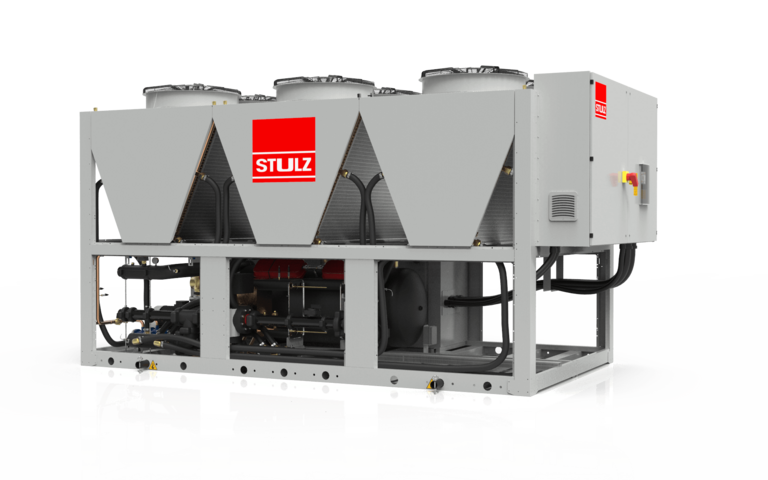

STULZ Explorer WPA

Air-cooled chiller systems for a cooling capacity of 160 to 565 kW

WSA: 378 – 1,200 kW

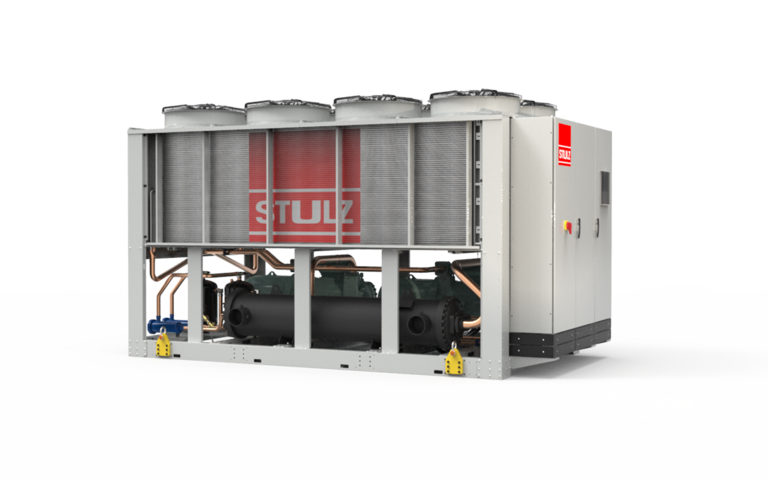

STULZ Explorer WSA

Air-cooled chiller systems for a cooling capacity of 370 to 1260 kW

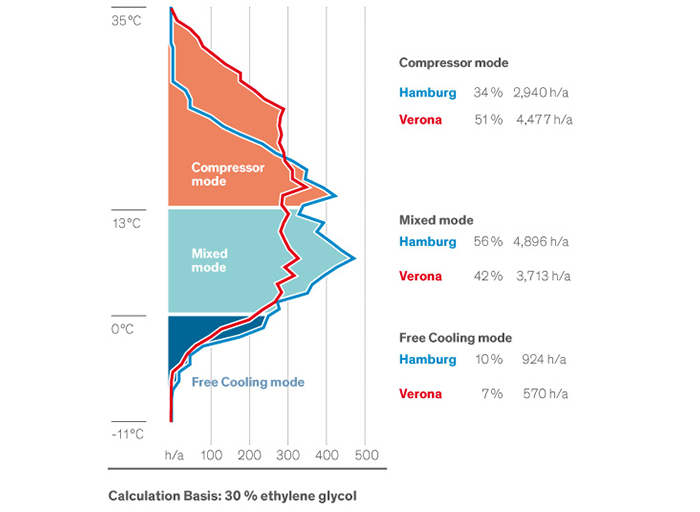

Indirect Free Cooling in the Explorer range

The STULZ Explorer range is available in Free Cooling version, which allows significant energy savings, mainly in cold and moderate climate. Free Cooling uses the external air to cool the fluid and may entirely replace the cooling circuit, enabling the compressors to be switched off.

Free Cooling calculator

Calculate the potential of Free Cooling at your location.

Low noise

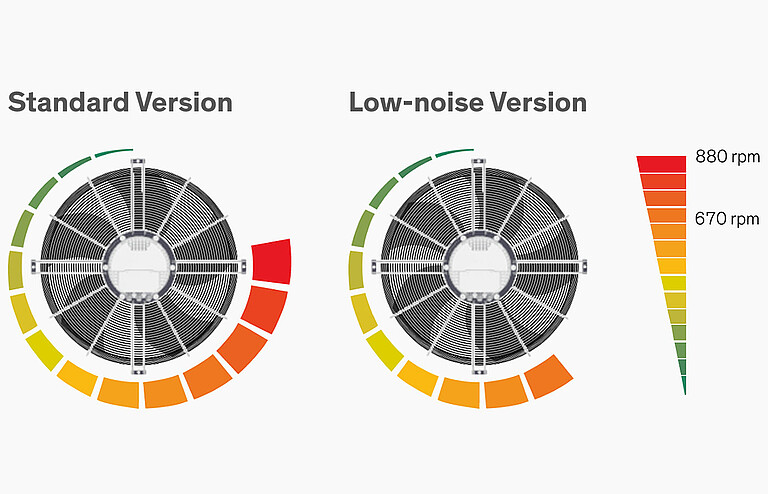

The compressors, fans and pumps are the only noise sources with the Explorer units. Depending on operating conditions, the noise level of the chiller can be reduced by up to 10 dB. To do this, the maximum fan speed is restricted during operation. Furthermore, cooling capacity that is comparable with the standard version can be attained with the low-noise version due to the matching of condensers and fans.

Figure right: Restriction of fan speed – To reduce noise emission, the fan speed is reduced by approx. 30% by the use of a star-delta circuit.

Air-cooled chiller systems: Control and monitoring

- Programmable to project-specific requirements

- Modern, high-resolution touch screen

- Intuitive navigation

- Update and event protocol via Micro SD

- Ethernet, ModBus, RTU, HTTP, SNMP

- Monitoring via Internet

- Future-oriented hardware and software design

Service and maintenance

As a company with locations across the globe, we offer everything you need in the extremely dynamic world of information technology – plus professional advice in the right place at the right time.

Our trained and experienced sales and service partners are located in over 140 countries. The resulting proximity to our customers allows fast response times. In addition, regular training courses and an active exchange of information ensure high quality and an extensive knowledge of all our products. This way, you can be sure your products are in the best hands and get the right maintenance – all over the world.

Reference: Stadium Galgenwaard

Chiller cooling for a soccer stadium: A project in collaboration of STULZ GROEP B.V., Jadikoel B.V. and Stadium Galgenwaard.

Read our Stadium Galgenwaard project story

Test Center

At our modern test center, each of our STULZ Explorer units is tested before leaving our plant grounds.

If you wish you also can request and witness a performance test under your individual operating and site conditions. This creates transparency and confirms the unit's performance and energy consumption.