CyberCool Indoor

Maximum precision for fluctuating heat loads

STULZ CyberCool Indoor provides powerful, highly efficient indoor chilled water cooling with a minimal footprint and is perfectly suited for cooling medical equipment, IT and facilities. The unit's modern design and compact construction allows it to be installed inside the building easily, as well as integrated in existing systems. The version with speed-controlled EC compressor was developed for especially stringent project requirements.

Product Overview

Most important benefits

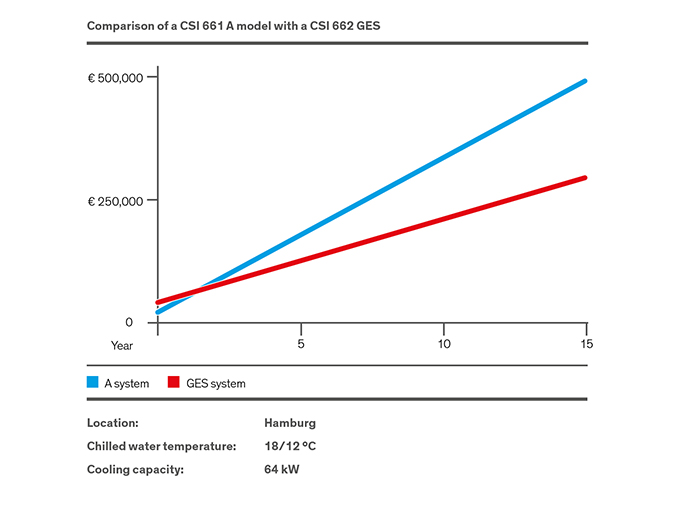

- Integrated Free Cooling function for low total operating costs (GE/GES system)

- Customized adaptations and special solutions for every application

- Installation in the immediate vicinity of the consumer

Most important features

- Available with and without EC compressor

- Three different systems available

Most important technical data

- Cooling capacity (kW): 20 – 100

- Integrated Free Cooling function for low total operating costs (GE/GES system)

- Customized adaptations and special solutions for every application

- Installation in the immediate vicinity of the consumer

- Quiet condensers or dry coolers minimize noise emission outdoors

- Simple to integrate in existing chilled water networks

- Chiller for indoor installation

- Available with and without EC compressor

- Three different systems available

| Cooling capacity (kW) | 20 – 100 |

| Sizes | 2 |

| Dimensions | Height (mm): 1,980 Width (mm): 950 – 1,400 Depth (mm): 890 |

| Cooling Systems | air-cooled (A/AS), water-cooled (G/GS), hybrid Free Cooling system (GE/GES) |

| Refrigerants | R410A (GWP: 2,088) |

Need more information?

Download our brochure!

All details about CyberCool Indoor

Simple setup and integration

The compact CyberCool Indoor also fits through standard doors and can be set up anywhere without any problems. Spatial segregation of the two noise sources and the use of especially quiet condensers or dry coolers minimizes overall noise emissions. As all the important components are integrated in the CyberCool Indoor, its sensitive technology is perfectly safe inside the building. What is more, CyberCool Indoor is perfectly protected from vandalism or accidental damage.

Chiller available in three cooling systems

Always the right choice: CyberCool Indoor with three cooling systems

In order to guarantee chilled water generation to suit requirements, CyberCool Indoor is available in two versions and three different systems. The systems allow for scalable planning and grow at the same pace as your future requirements.

Energy efficiency, investment volume, operating costs, room size, noise protection, redundancy and local climate – every project has its own requirements in terms of appropriate indoor chilled water generation. Our customers can choose between different configurations and so achieve an ideal balance between capital investment, running costs and energy efficiency. STULZ is the world's only manufacturer to offer such a huge range of configuration options.

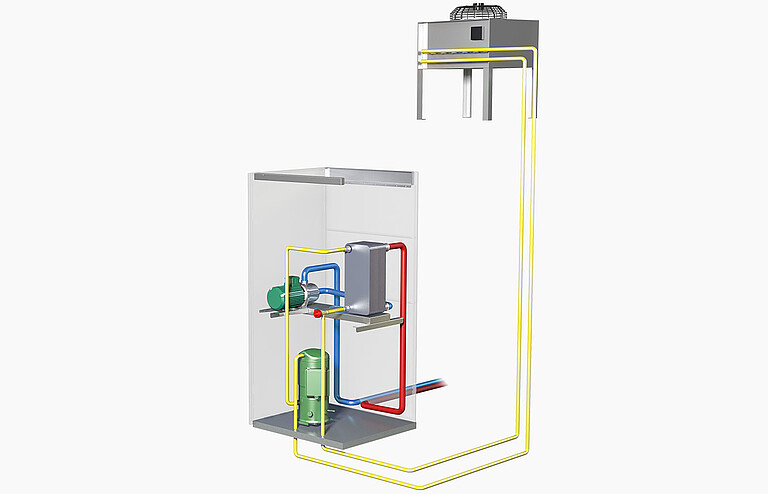

Air-cooled (A/AS)

The compact standard solution

A chilled water circuit transfers the heat load to the evaporator where the heat is drawn from the water and passed to the refrigerant. The refrigerant gives off the heat to the outside air via an air-cooled condenser.

Benefits of the system

- Tried and tested, rugged technology

- Reduced to just the major components

- Refrigerant used as transport medium for optimum heat transfer

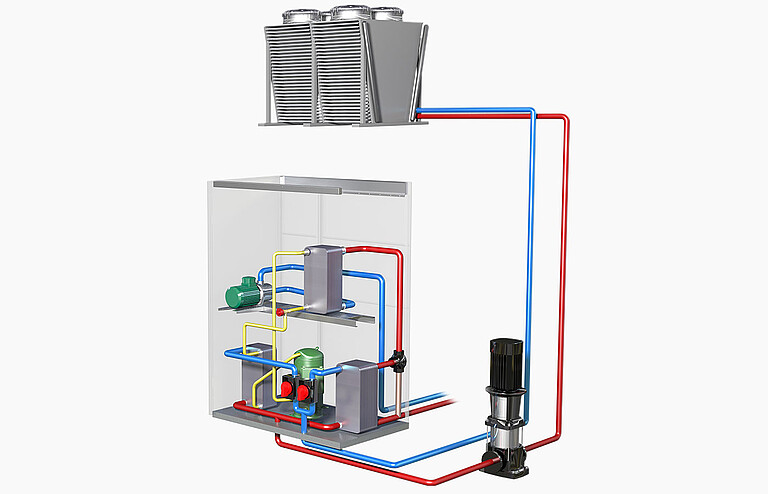

Water-cooled (G/GS)

Water-cooled: Quiet and easy to integrate (G/GS)

Like A/AS on the direct evaporator principle – with one difference: the heat is transferred to a water/glycol mixture via an integrated plate condenser; this mixture gives off its heat to the outside air in a closed circuit via an external dry cooler.

Benefits of the system

- Integrable in existing chilled water networks

- Dry cooler can be linked to several units

- Pumps allow a large distance between the CyberCool Indoor and the dry cooler

Water-cooled with integrated Free Cooling function (GE/GES)

Maximum efficiency

Like G/GS, but with Indirect Free Cooling which replaces energy-intensive compressor operation in part or in full when outside temperatures are low. In FC mode, the heat is transferred straight to the chilled water circuit by an integrated Free Cooling heat exchanger and given off into the outside air via an external dry cooler.

Benefits of the system

- TCO leader: Minimal total operating costs over runtime

- All Free Cooling (FC) components integrated in the unit

- The most efficient system thanks to intelligent switching of operating modes (DX - mixed - FC)

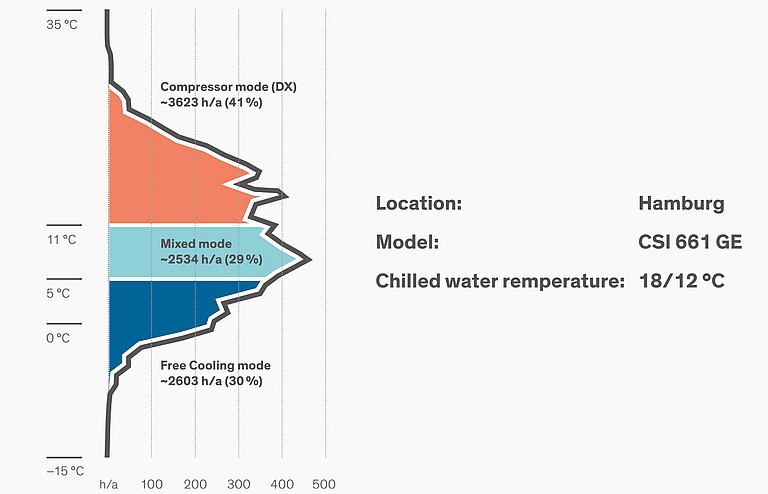

Maximum efficiency with Free Cooling

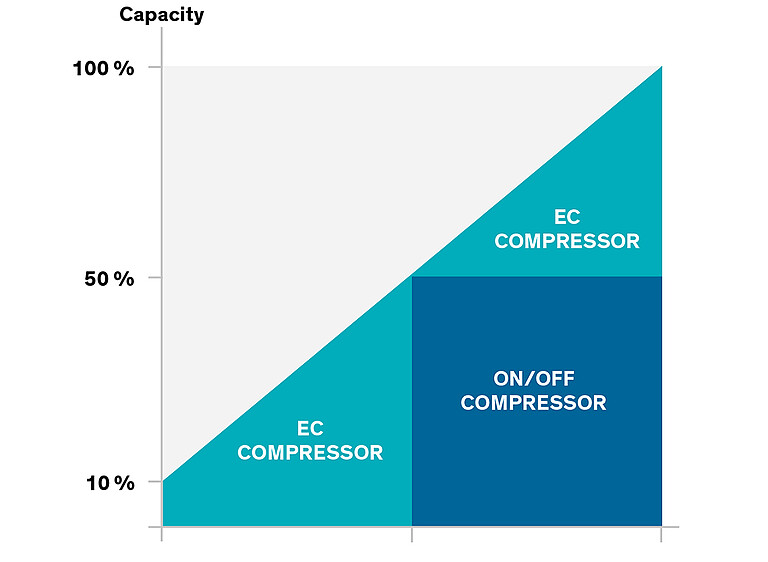

The CyberCool’s most efficient mode for indoor cooling is selected automatically depending on outside temperature – reliably throughout the whole year and whatever the local temperature profile.

Compressor mode (DX): At high outside temperatures, entire cooling capacity is achieved using the compressor. The use of perfectly-matched components means that the CyberCool Indoor already works extremely efficiently, even in this mode.

Mixed mode: At moderate temperatures, the CyberCool Indoor runs in energy-efficient mixed mode, a mixture of free cooling and significantly-reduced compressor cooling.

Free Cooling mode (FC): At low outside temperatures, free cooling delivers the greatest potential savings. In this case, only outside air is used for cooling, compressor cooling is switched off completely.

(Illustration at right: temperature profile of Hamburg)

CyberCool Indoor EC – the TCO leader

Optimal cooling generation for mission-critical applications

Control and monitoring

- Project-specific software development and optimization

- Compatible with all common BMS protocols

- Runtime comparison and alarm switching ensure availability

- Machine-independent parallel operation of several chillers

- Sophisticated warning and alarm system

Options

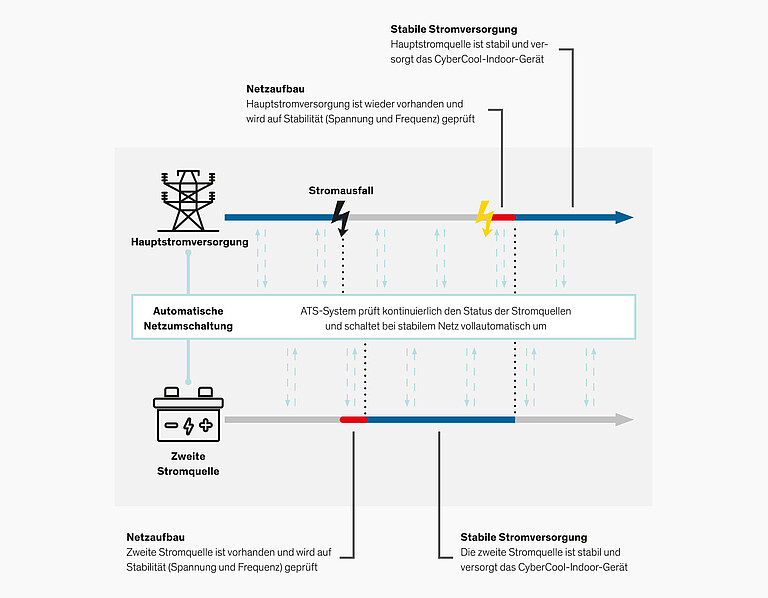

Second power source for the greatest possible reliability

One of the key requirements for mission-critical and sensitive applications is uninterrupted cooling - in the event of a power outage, for example. To guarantee stable cooling capacity in spite of this, STULZ provides the option of an automatic transfer switch fitted directly in the switch gear cabinet. If the primary power supply fails, this is detected automatically and the system defaults to a second power source within a minimum of 180 ms.

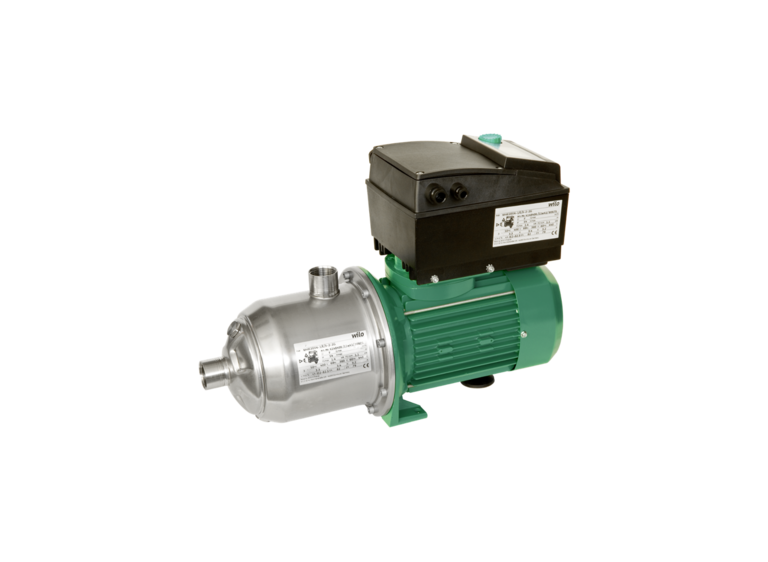

Double pump

- Additional chilled water pump for internal redundancy

- Standard (2 bar) and high pressure (3 bar) version available

- Normal-priming multistage pumps

- All water-bearing parts are stainless steel Made in Germany

Water pipings

- Water pipings lateral, at the back or above possible (standard: at the bottom)

- Several pipe connections possible, e.g. Victaulic or flange (standard: screw connection)

Speed-controlled pump

- Efficient partial load operation

- Exact adjustment of discharge head and volumetric flow to the chilled water system

- Normal-priming multistage pump with integrated frequency converter

- Made in Germany

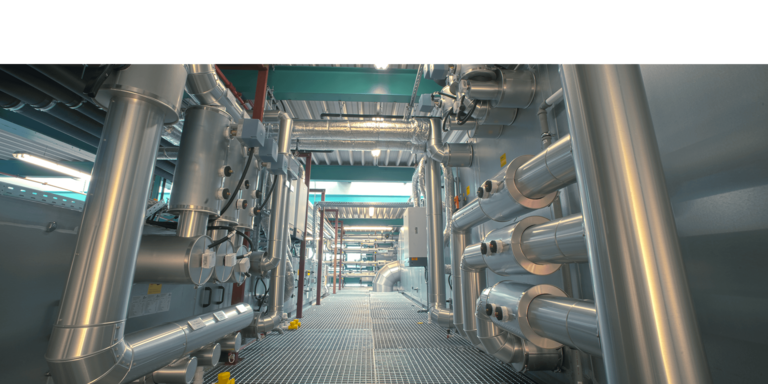

Project story: Cooling in perpetuity

STULZ implements air conditioning solution for RAG data center at the former colliery Pluto

More demanding efficiency and safety requirements meant the RAG company needed a new data center. For its air conditioning, RAG chose a solution from STULZ. The new units enable Mixed mode with an infinitely variable combination of Free Cooling and DX cooling, for greater energy efficiency.

Climate. Customized.

From standard units to fully customized solutions

The ability to offer such a wide range to customers is the embodiment of our philosophy, "Climate. Customized.". Size, design, system or control: CyberCool Indoor is a model of adaptability and the chiller units can be precisely adapted to your individual requirements. In addition, a variety of options and equipment versions are available to achieve the optimum result.

Learn more about Climate. Customized.

Service and maintenance

As a company with locations across the globe, we offer everything you need in the extremely dynamic world of information technology – plus professional advice in the right place at the right time.

Our trained and experienced sales and service partners are located in over 140 countries. The resulting proximity to our customers allows fast response times. In addition, regular training courses and an active exchange of information ensure high quality and an extensive knowledge of all our products. This way, you can be sure your products are in the best hands and get the right maintenance – all over the world.

Locations worldwide

Test Center

CyberCool Indoor units are subjected to a full computer-controlled check in the STULZ Test Center. Extensive measurements under a wide variety of conditions show the actual performance data of the systems and components, bringing transparency to the theoretical design data.