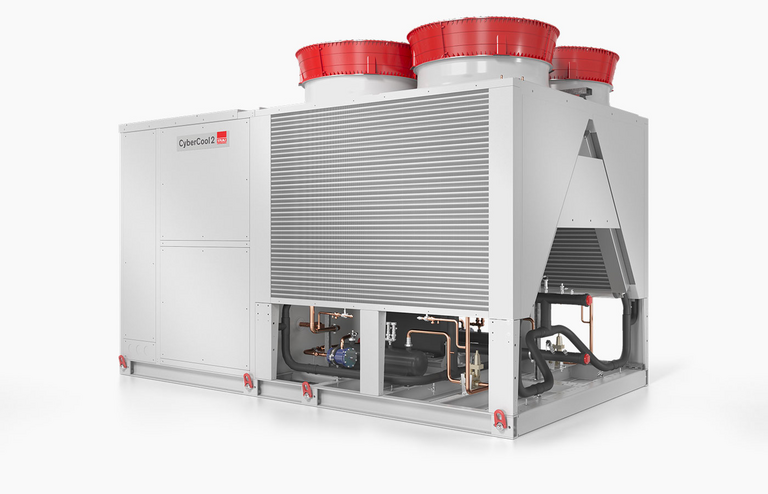

CyberCool 2

The benchmark of Free Cooling chillers

The CyberCool 2 enables you to operate with maximum energy efficiency and optimum reliability for complex, demanding and uncompromising chilled water solutions. At the same time, the completely new overall concept of all components ensures low sound emissions in noise-critical applications. The result is a sustainable range of chillers that meets every eco-design directive.

Product Overview

Most important benefits

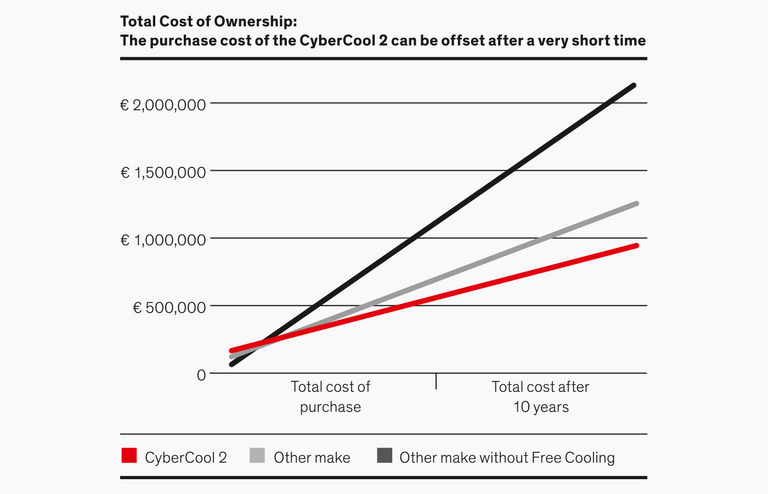

- TCO leader: Lowest total cost of ownership through Free Cooling and a unique "Mix Mode Boost”

- Flexible adaption to every project through 12 sizes, 5 versions, 2 designs and various options

- Minimum noise emissions with maximum energy efficiency

Most important features

- Designed especially for mission-critical applications, such as data centers and industry as well as suitable for medical sector

- Maximum possible efficiency through Indirect Free Cooling

- Outdoor installation on the roof or next to the building

Most important technical data

- 191 models in 12 sizes

- Cooling capacity (kW): 50 – 1,400

- Refrigerants R410a (GWP: 2.088), R134a (GWP: 1.430), R1234ze (GWP: 7)

- TCO leader: Lowest total cost of ownership through Free Cooling and a unique "Mix Mode Boost”

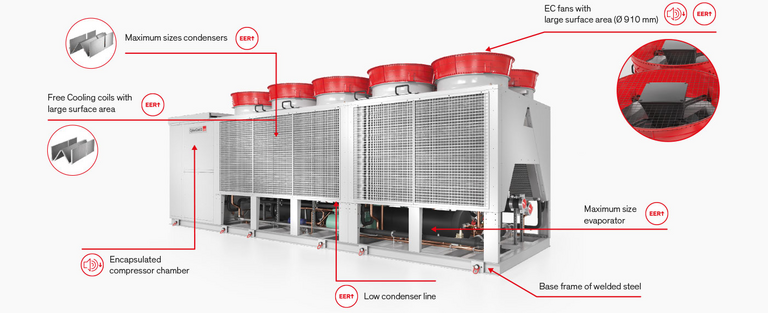

- Maximum size components ensure low energy consumption

- Maximum possible efficiency through Indirect Free Cooling

- Flexible adaption to every project through 12 sizes, 5 versions, 2 designs and various options

- Specially developed for mission-critical applications

- Ongoing quality management during production

- Minimum noise emissions with maximum energy efficiency

- Highest sustainability standards and ErP 2021 compliance

- Designed especially for mission-critical applications, such as data centers and industry as well as suitable for medical sector

- Safe operation at outdoor temperatures from -40 to +60 °C

- Broad operating range with chilled water inlet temperatures up to +33 °C and chilled water outlet temperatures up to +22 °C

- Available in 28 versions with:

- Standard, Free Cooling or Non-glycol2

- Screw or scroll compressor

- Power- or noise-optimized

- Refrigerants: R134a (GWP 1430), R513A (GWP 631) und R1234ze (GWP 7)

- Adiabatic wet-pad system - Made and Engineered in Germany

- Outdoor installation on the roof or next to the building

| Cooling capacity (kW) | 50 – 1,400 |

| Sizes | 12 |

| Dimensions | Length (mm): 2,300 – 12,785 Depth (mm): 1,300 – 2,300 Hight (mm): 2,350 – 2,510 |

| Refrigerants | R410a (GWP: 2,088) R134a (GWP: 1,430) R1234ze (GWP: 7) |

Need more information?

Download our brochure!

All details about CyberCool 2

Low energy consumption

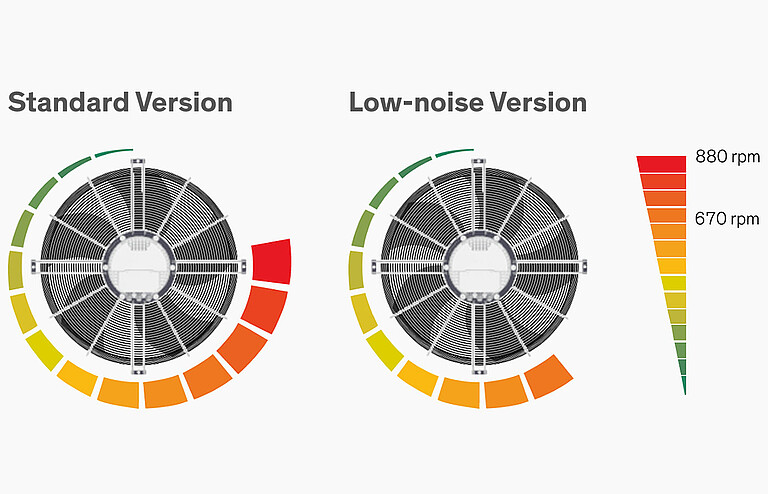

Energy efficiency vs. low noise – Your priority in focus

Saving energy at the expense of reliability? Less noise emissions at the expense of energy efficiency? STULZ chilled water solutions make no compromises. With the CyberCool 2, the optimum operating point can be achieved for every project: Depending on priority, energy efficiency, noise emissions or both can be individually optimized. The following examples show the variable range of applications for the CyberCool 2.

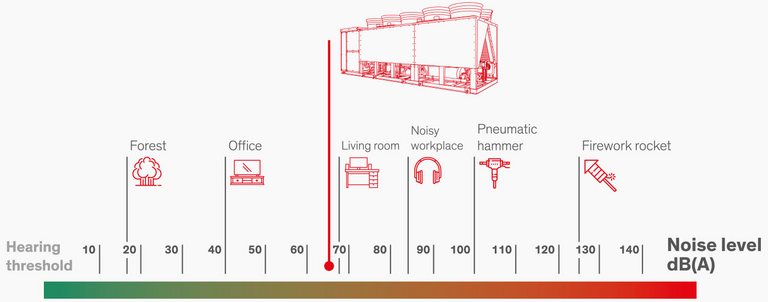

Noise-optimized version

Chilled water systems by STULZ: Powerful and quiet

Where there are people, noise emissions should always be kept to a minimum. This applies in commercial and industrial zones, and even more so in the vicinity of offices, hospitals and residential areas. The CyberCool 2 is equipped with components that lower noise emissions to a most impressive minimum.

Climate. Customized.

From standard units to fully customized solutions

The ability to offer such a wide range to customers is the embodiment of our philosophy, "Climate. Customized.". Size, design, cooling capacity or control: STULZ’s CyberCool 2 can be precisely adapted to your individual requirements. In addition, a variety of options and equipment are available to achieve the optimum result.

Learn more about Climate. Customized.

Options

- Integrated UPS

- Compressor soft start

- VSD pumps

- Energy meter in the electrical cabinet

- Corrosion protection

- Axitop

- Hinged Fans

- Weather roof

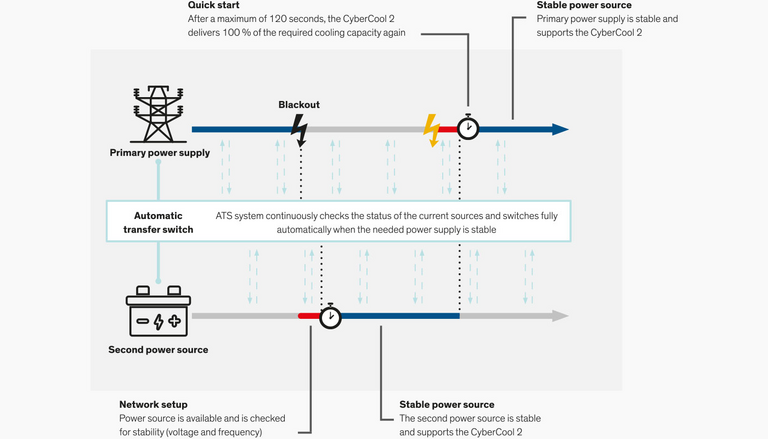

The ideal option with automatic transfer switch for your reliability

One of the key requirements for mission-critical and sensitive applications is uninterrupted cooling – in the event of a power outage, for example. To guarantee stable cooling capacity in spite of this, STULZ provides the option of an automatic transfer switch fitted directly in the switch gear cabinet. If the primary power supply fails, this is detected automatically and the system defaults to a second power source within a minimum of 180 ms.

Model overview for your mission-critical applications

CyberCool 2 with screw compressors

Sizes |

8 |

| Cooling capacity (kW) | 400 – 1,400 |

| Dimensions | Height (mm): 2,510 Width (mm): 2,300 Depth (mm): 5,030 – 12,785 |

CyberCool 2 with scroll compressors

Sizes |

4 |

| Cooling capacity (kW) | 130 – 600 |

| Dimensions | Height (mm): 2,510 Width (mm): 2,300 Depth (mm): 3,950 – 7,250 |

CyberCool 2 mini with scroll compressors

Sizes |

2 |

| Cooling capacity (kW) | 50 – 130 |

| Dimensions | Height (mm): 2,350 Width (mm): 1,300 Depth (mm): 2,300 – 4,200 |

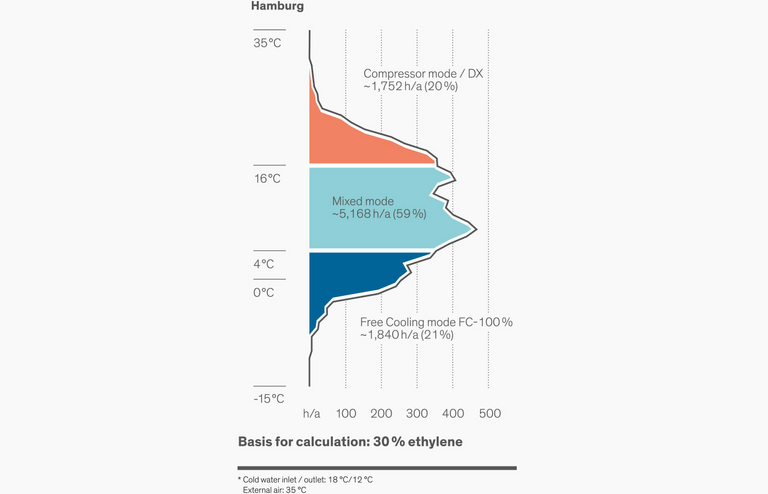

Free Cooling – maximum possible efficiency

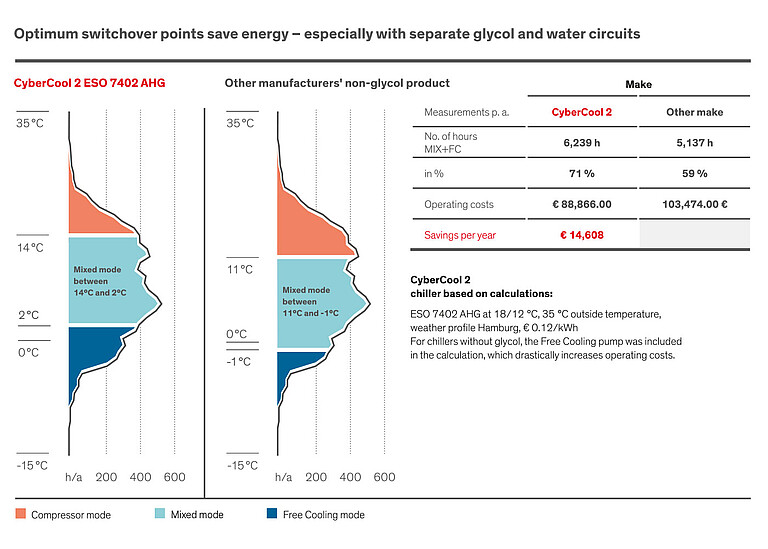

The Free Cooling of the CyberCool 2 uses the outside temperature, which offers the greatest potential savings of all, especially in cold and temperate climates.

When outside temperatures are low, Free Cooling can completely replace energy-intensive compressor cooling. In temperate climates, the CyberCool 2 runs in energy-efficient Mixed mode for most of the year, i.e. with a mixture of Free Cooling and compressor cooling.

CyberCool 2 – Top of the class in energy:

- Early switchover to Free Cooling

- Maximum use of Free Cooling coils between compressor mode and Free Cooling

- Coils designed to allow the maximum surface area

Free Cooling calculator

Calculate the potential of Free Cooling at your location.

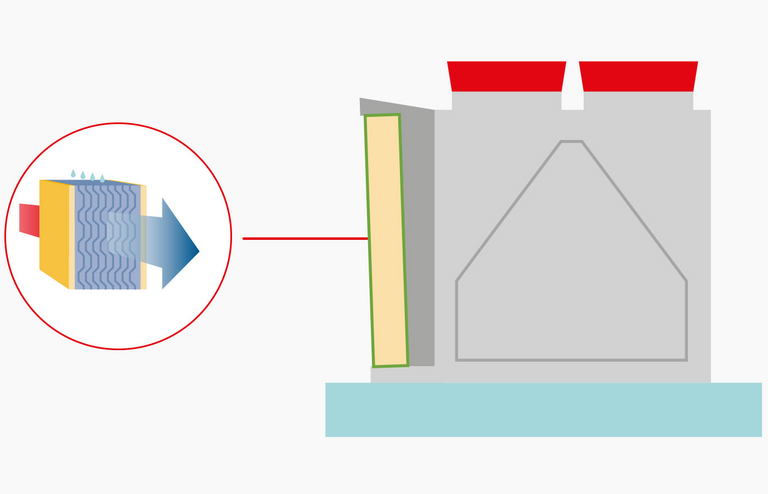

Adiabatic system for even more Free Cooling

Benefit from the effect of adiabatic evaporative cooling. The adiabatic system with wet pads extracts heat from the outside air and increases the cooling effect. This enables the chilled water circuit to be cooled much longer via the outside air, which significantly extends the Mixed and Free Cooling mode. The result is minimum compressor running time and a reduced condensation temperature – and therefore a minimization of the operating costs.

Benefits of the adiabatic system:

- Saturation efficiency 89 %

- Highly efficient distribution system

- Reuse of water

- No water droplet entrainment (aerosol)

Non-glycol version: Free Cooling without glycol

There are some buildings where glycol cannot be used. Therefore, with the "Non-glycol2 option" glycol is now only used in the Free Cooling circuit. This option provides the benefits of Free Cooling while refraining from the use of glycol in the building.

However, by separating the Free Cooling and chilled water circuits with an additional brazed plate heat exchanger, the switchover points to Free Cooling and Mixed mode do shift by a few degrees Celsius. To be energy-efficient, the chiller must run in Mixed and Free Cooling mode as early as possible.

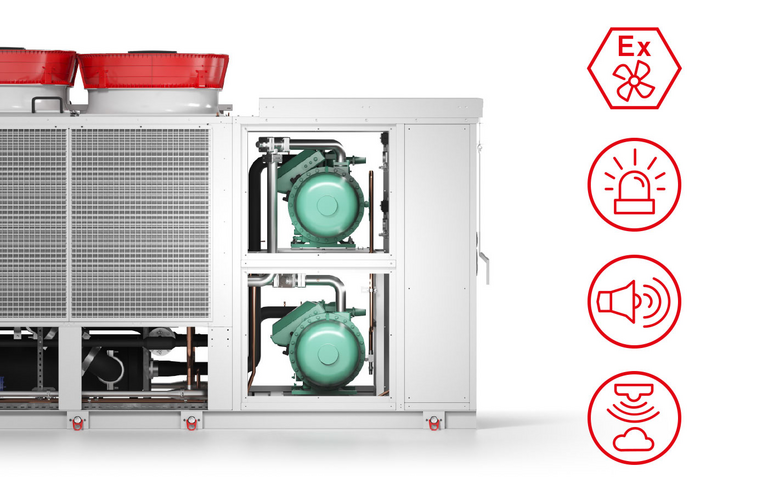

Sustainable low-GWP version with R1234ze refrigerant

Units of the CyberCool 2 ze series are equipped with the refrigerant R1234ze. Due to its low global warming potential (GWP: 7), the refrigerant is particularly sustainable and classified according to the A2L class of hazardous substances. The refrigerant thus has low toxicity and low burning rate. In order to relieve operators of the underlying requirements (standard EN 378), the units are equipped with a special safety concept.

Service and maintenance

As a company with locations across the globe, we offer everything you need in the extremely dynamic world of information technology – plus professional advice in the right place at the right time.

Our trained and experienced sales and service partners are located in over 140 countries. The resulting proximity to our customers allows fast response times. In addition, regular training courses and an active exchange of information ensure high quality and an extensive knowledge of all our products. This way, you can be sure your products are in the best hands and get the right maintenance – all over the world.

Locations worldwide

Projects

Test Center

In our state-of-the-art, 700-square-meter Test Center with its various climate chambers, we can perform a variety of tests on precision air conditioning units and chillers. During the development of the CyberCool 2, we were able to test and optimize it under all climatic conditions encountered around the world. In addition, we offer you the opportunity to book a witness test in our Test Center. This allows you to have the desired air conditioning system tested according to your exact specifications, creating transparency and providing you with information about your system’s performance and energy consumption.

Read more about our Test Centers