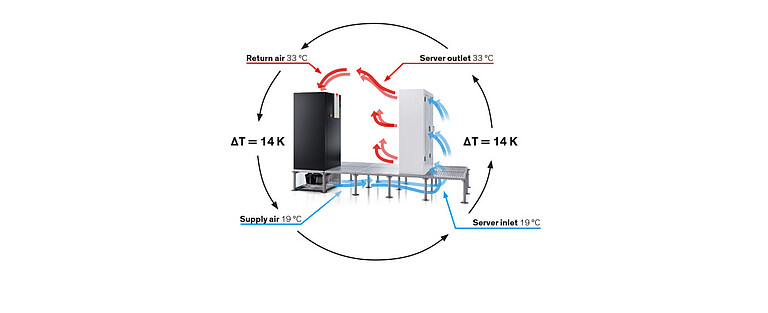

A server in a Data Center takes in air at a certain temperature. Once inside the server, this air warms up due to the heat produced by all the components in the server. The air that then exits the server is roughly 10 °C to 15 °C hotter.

An air conditioning unit in a Data Center also takes in air at a certain temperature. Inside the air conditioning unit, this air is cooled and the extracted heat conveyed to the outside. So the air that exits the air conditioning unit is approximately 10 °C to 15 °C cooler.

That all works out fine then, doesn't it? Unfortunately not.

The above-mentioned 10 °C to 15 °C is the so-called air-side temperature difference, or Delta T.

In a theoretical ideal scenario – a closed circulation of air between the server and the air conditioning unit – there would be a certain air-side temperature difference, and the air conditioning unit would work at its planned maximum level of efficiency.

In a real Data Center, this is sadly not the case. The cold air exits the air conditioning unit, flows through the raised floor, enters the cold aisles through the perforations in the raised floor grilles, is sucked in by the server, heated, blown out into the hot aisle, and then begins its journey back to the air conditioning unit. However, air is stupid and lazy. It doesn't know that this is the route it has to take, and showing it the way with blue and red arrows is no help at all.

Some of the air finds openings in the raised floor, e.g. cable cut-outs in the hot aisle that have not been sealed, gaps between the raised floor grilles or even grilles missing altogether below the racks. It then takes one of these shortcuts back to the hot aisle and straight back to the air conditioning unit, without ever having seen a server from the inside or having taken any of its heat away with it. Other bits of air take the planned route into the cold aisle, but then sneak between the servers through unused rack surfaces, or to either side of the servers, hot-footing it straight to the hot aisle and back to the air conditioning unit. This air does absorb a little heat, which the servers radiate to the outside.

Air that takes in only very little heat on its trip through the Data Center lowers the air-side temperature difference and therefore the efficiency of the entire air conditioning system.

Here's an example:

With an airflow of 45,000 m³/h and a Delta T of 15 °C (return air 35 °C, supply air 20 °C), an ASD 2010 CWU air conditioner from STULZ manages a capacity of 228 kW for a power consumption of 6.2 kW. The result is an energy efficiency ratio (EER) of 36.8.